Excellence in weaving preparatory

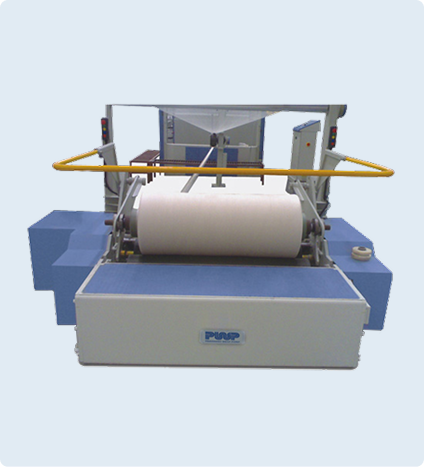

Long Chain Beamer

Creating the Tradition in Indigo

Long Chain Beamer

- Low profile height allows easier access to the comb and provides improved observation.

- Fabricated side cabinets with sealed doors provide a lint free ventilated environment for electronics.

- Functional operator controls grouped in one control panel improves operator performance.

- Equipped with frequency controlled AC drive designed for a gear-in speed of 500mpm.

- Direct beam drive from motor to the drive spindle by means of a poly-V belt

- Movable foot operated START/STOP switch located along the front of the beamer for operator convenience.

- Three quick-acting pneumatic brakes are provided to prevent broken ends from being wound into the warp beam.

- Each brake is individually set and controlled for precise adjustment and synchronization.

- Loading/Unloading of the beam is accomplished by simple operator control which extends and retracts the tail-stock bearing support.

- Predetermined counter sets the yarn length for each beam and automatically activates an indicator light to signal the operator that a lease string is approaching.

- Lease string detector automatically stops the machine before a lease string reaches the comb.

- Comb mounted behind the carrier roll facilitates warp yarn adjustment from side to side and width adjustment.

- Chromium-plated flattening bar is located behind the comb to support the yarn sheet at the desired height.